Taking a build to the next level.

I use wood binding on some of my builds and it’s available as an option on custom orders. While plastic ABS is flexible and relatively straight forward to install, wood binding can bring a unique set of challenges during the installation process. Wood binding has to be heated and carefully bent to the contours of the guitar. If too much heat is used it will burn, if not enough is used it will crack. Using high heat and steam I can get the wood fibers into a temporary state where they can be manipulated and bent. When the fibers cool back down they hold the their new shape.

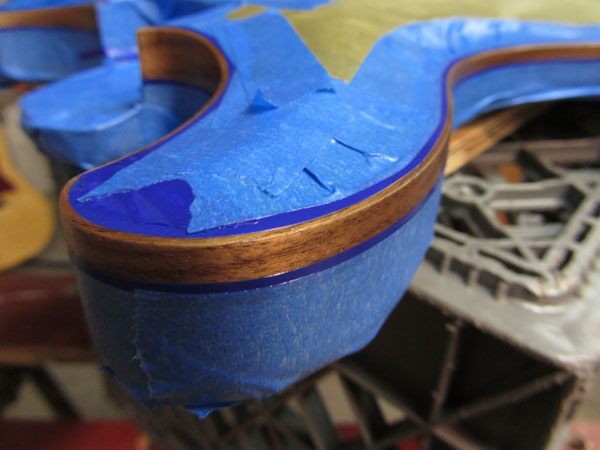

Woods such as cocobolo are resistant to water and therefor resistant to some adhesives. Adhering oily wood binding to the guitar has some challenges. Troublesome timber like this requires a two part adhesive and must be tightly bound during bonding to insure a solid bond.

When binding with ABS I usually leave it a few thousandths of an inch taller than needed and scrape it level after staining and painting (but before clear coating). Wood binding on the other hand needs to be sealed to keep stain and paint from soaking into its grain. This means extra time taping and masking off the guitar before the sealer can be applied. Binding using hardwoods is time consuming and therefor a bit more expensive that standard ABS binding but the payoff is quite nice.

No comments yet.